Hyson Industry delivers high-performance Steel Box Girder Formworkdesigned to meet the exacting standards of large-scale infrastructure projects, including high-speed railways, elevated expressways, and sea-crossing bridges. With over 15 years of experience in Nantong—China’s construction hub—and a portfolio that includes the Sutong Bridge, we understand that structural integrity starts with the mold.

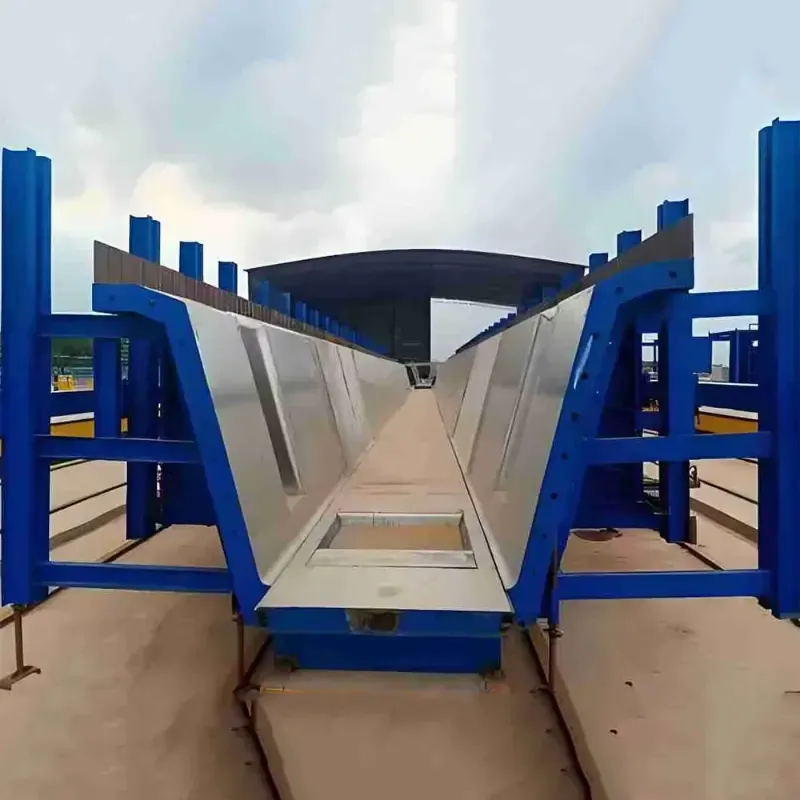

Our Box Girder Formwork system is not just a steel structure; it is a precision tool. Fabricated from premium Q235/Q345 steel and refined through our patented design processes, our molds ensure monolithic castingwith zero leakage. For precast concrete factories, our hydraulic collapsible inner mold system significantly reduces demolding time, boosting production cycles. For contractors, the modular design ensures easy assembly and adjustment on-site. Whether you require segmental box girders or full-span precast molds, Hyson is your trusted partner for safety, efficiency, and superior concrete finishes.

Technical Specifications

| |

| High-Strength Q235B / Q345 Steel |

| 6mm, 8mm, or 10mm (Customized for load bearing) |

| Hydraulic / Mechanical Adjustable System |

| |

| Sandblasting + Anti-rust Paint / Oiled |

| CO2 Shielded Welding, Full Penetration |

| ≥ 200-500 times (Depending on maintenance) |

| ISO 9001:2015, CCCC/CRCC Qualified Supplier |

Product Features

- Robust & Deformation-Resistant: Manufactured with Q235B high-strength steel and reinforced ribbing, our forms withstand immense concrete pressure without bulging, ensuring structural safety.

- Hydraulic Efficiency: Optional integrated hydraulic cylinders allow for one-touch stripping and repositioning of the inner mold, significantly reducing labor intensity and crane usage.

- Leak-Proof Precision: Our proprietary sealing technology and precision machining prevent slurry leakage ("honeycombing"), delivering a clean, smooth concrete surface that requires no plastering.

- Modular & Versatile: Standardized connection components and adjustable panels allow the formwork to be modified for different beam lengths and curves, maximizing asset value for rental companies.

- Rapid Assembly: Designed with quick-lock pins and alignment guides, the system minimizes on-site assembly time, helping contractors meet tight deadlines.

Application Scenarios

- High-Speed Railway Bridges: Mass prefabrication of single and double-track box girders in precast yards.

- Highway Interchanges & Viaducts: Suitable for variable cross-section continuous beams and ramps.

- Precast Beam Yards : High-precision molds for precast segmental box girders (Match-casting method).

- Sea-Crossing Bridges: Heavy-duty corrosion-resistant molds capable of withstanding harsh marine construction environments.