Cuplock ScaffoldingPopular

Cuplock Scaffolding System | Heavy-Duty Modular Support & Access

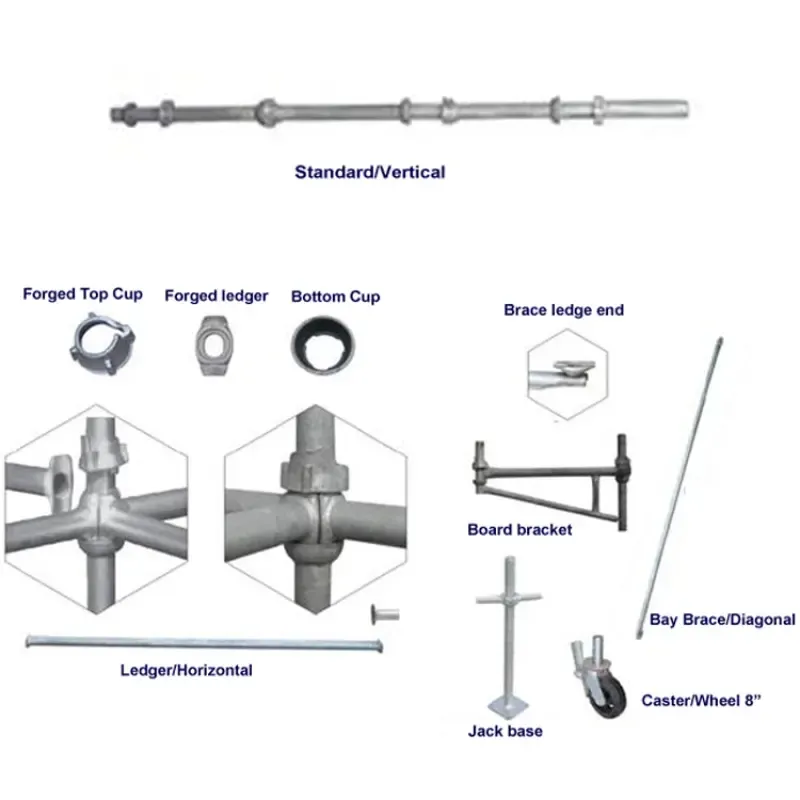

Unlike systems that require nuts, bolts, or wedges, Hyson’s Cuplock features a unique circular node point that allows up to four components to be connected in one fastening action. This "cup" locking mechanism is not only vibration-resistant but also eliminates the risk of losing loose fittings on-site. Crafted from high-grade Q235/Q345 steel with drop-forged top cups, our system offers superior resistance to cracking and deformation compared to standard cast-iron alternatives. Whether you are a rental company needing a low-maintenance fleet or a contractor building complex bridge supports, Hyson delivers the structural integrity you can trust.

Hyson Industry’s Cuplock Scaffolding System is a multi-purpose steel scaffold system renowned for its unique node point locking device. Unlike systems with tedious loose bolts, our design utilizes a fixed bottom cup and a sliding top cup, allowing up to four horizontals to be secured in a single hammer action. This not only speeds up erection by 30% but also eliminates the risk of losing small components on site—a major pain point for rental companies.

Manufactured in our Nantong facility, Hyson Cuplock is engineered for high-load bearing applications. We use Drop Forged Top Cups (instead of malleable cast iron) to ensure maximum impact resistance and longevity. Whether supporting heavy concrete formwork for bridges (like our work on the Sutong Bridge) or providing access for industrial maintenance, Hyson Cuplock delivers a rigid, safe structure you can trust.

Technical Specifications

| |

| |

| High-Strength Carbon Steel Q235 / Q345 |

| |

| 3.25mm / 3.0mm / 2.75mm (Customizable ) |

| Top Cup: Drop Forged ; Bottom Cup: Pressed Steel |

| Hot Dip Galvanized (HDG) or Painted/Powder Coated |

Product Features

No Loose Fittings = Lower Loss Rate

The fixed bottom cups and captive mobile top cups mean there are no loose nuts, bolts, or wedges to manage. For rental companies, this significantly reduces inventory loss and simplifies material management upon return.

Fast & Secure Locking Mechanism

A single hammer blow to the top cup secures up to four horizontals. This simple action speeds up erection by 30-50% compared to tube and fitting scaffolds, reducing labor costs and accelerating project timelines.

Forged for Strength

Unlike cheaper competitors who use brittle cast iron, Hyson uses drop-forged steelfor the critical top cups. This ensures the node can withstand high impact and heavy loads without cracking, ensuring safety in high-risk bridge construction.

Versatile Geometry

The Cuplock node allows for flexible alignment of ledgers, enabling the scaffolding to easily follow curved building facades or circular industrial structures without complex tube bending.

Application Scenarios

Bridge Formwork Support (Shoring): Providing stable, high-capacity support for heavy concrete slabs and beams (Ideal for infrastructure projects like those by CCCC).

Curved Structures: The unique node allows ledgers to be rotated, making it perfect for circular tanks, curved walls, and towers.

Industrial Maintenance: Quick erection for refineries and power plants where time windows are tight.