Other FormworkPopular

Dolos Steel Formwork for Breakwater Construction | High-Precision Precast Molds

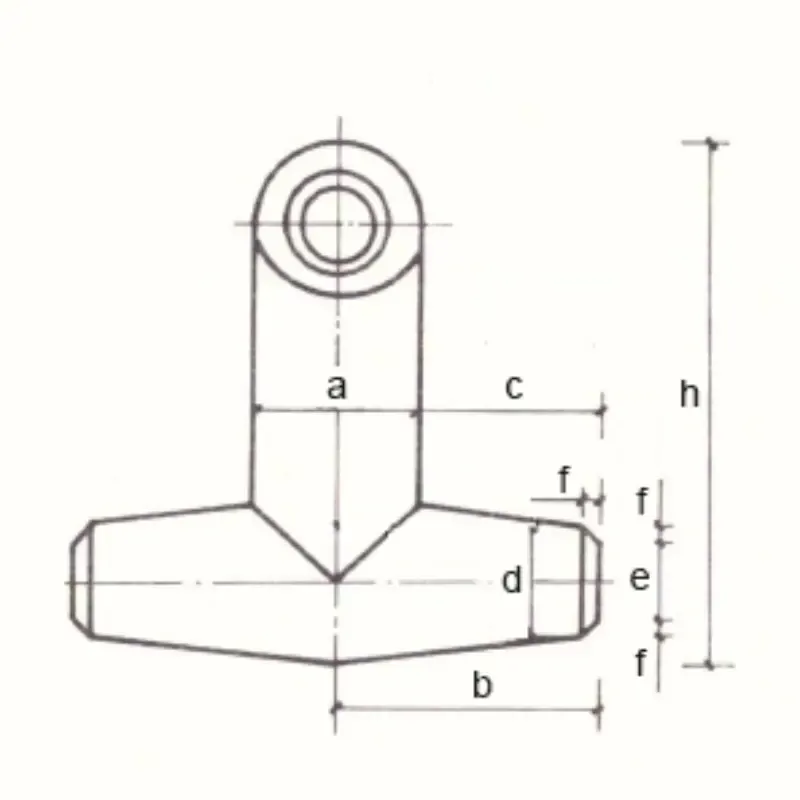

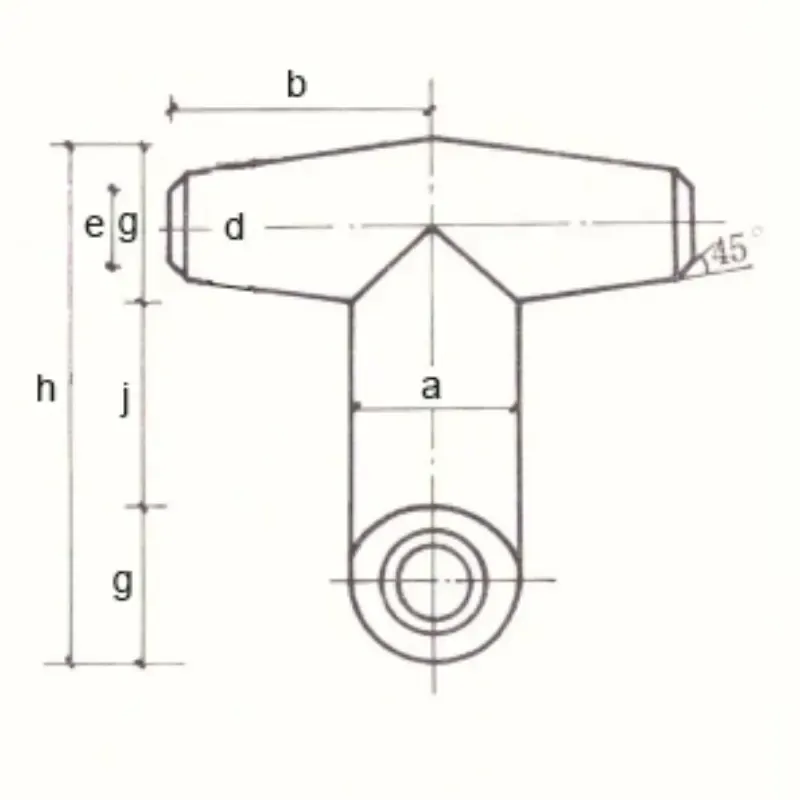

Dolos formwork refers to the steel molds used to cast dolosse, which are large, complex, interlocking concrete blocks designed for coastal protection to dissipate wave energy, built into breakwaters and revetments to prevent erosion. These specialized forms replicate the unique geometry of the dolos, allowing for mass production of these robust, anchor-shaped units that interlock naturally, offering superior stability and economy for shoreline defense.

Hyson Industry presents our premium Dolos Steel Formwork, specifically engineered for the mass production of wave-dissipating concrete blocks used in breakwaters and coastal protection projects. Understanding that the complex geometry of a Dolos block requires exceptional mold precision, we utilize advanced 3D modeling and CNC machining to ensure perfect symmetry and interlocking performance.

Unlike standard molds, Hyson’s solution focuses on production cycle efficiency. Our patented quick-release locking system allows for rapid assembly and disassembly, significantly reducing labor costs and increasing daily output for precast factories. Manufactured with high-grade Q235B steel and reinforced with robust stiffeners, our forms maintain dimensional integrity even after hundreds of pours, ensuring every concrete block meets strict international marine engineering standards.

Technical Specifications

| |

| High-Quality Carbon Steel Q235B |

| 5mm / 6mm / 8mm (Customizable based on tonnage ) |

| 1 Ton - 30 Tons (Supports custom sizes ) |

| ISO 9001:2015, Meets CCCC & CRCC Standards |

| Anti-rust Oil / Epoxy Paint |

| ≥ 500 times (Under proper maintenance) |

| |

Product Features

Precision Geometry for Perfect Interlocking

Leveraging our 15 years of experience and 12 design patents, we ensure that the complex curves of the Dolos are accurately formed. This guarantees that the final concrete blocks interlock securely, maximizing the stability of the breakwater structure.

Easy Demolding & "Clean Concrete" Finish

Our molds feature a polished interior surface and a smart segmented design that prevents concrete adhesion. This results in a smooth, pore-free surface finish—crucial for resisting saltwater corrosion—while minimizing the need for secondary repairs.

Rugged Durability for High Turnover

Built with premium Q235B steel and reinforced by expert welding (certified technicians), Hyson forms withstand the high pressure of concrete pouring and the wear of daily handling. Ideal for rental companies and long-term projects.

Standardized Fasteners for Rapid Assembly

We use standardized bolts and pins that are easy to replace and operate. This user-friendly design allows construction teams to assemble and strip the forms quickly, accelerating the project timeline.

Application Scenarios

Coastal Breakwaters & Sea Walls: Protecting coastlines from wave erosion.

Port & Harbor Construction: Ensuring calm waters for vessel docking.

Land Reclamation Projects: Providing a solid foundation for artificial islands.