Hyson Industry’s Ringlock Scaffolding System is the preferred choice for complex industrial projects and heavy-duty bridge construction worldwide. Engineered for speed, our rosette-based locking mechanism allows a single worker to secure connections with just a hammer, reducing erection time by up to 50% compared to traditional tube-and-clamp systems.

As a trusted supplier for CCCC and CRCC mega-projects, we refuse to compromise on material quality. We utilize high-strength Q345B steel for verticals and advanced automatic welding robotics to ensure every node is precise and secure. Finished with a premium hot-dipped galvanization (min. 75μm thickness), Hyson Ringlock is built to resist corrosion in the harshest marine and industrial environments, making it a high-ROI asset for equipment rental companies and a safety guarantee for contractors.

Technical Specifications

| |

| All-Round Ringlock Scaffolding |

| Standard (Vertical): Q345B / Ledger (Horizontal): Q235B |

| Ø48.3mm (Standard) or Ø60.3mm (Heavy Duty Shoring) |

| 3.2mm / 3.25mm / 4.0mm (Customizable) |

| Hot Dipped Galvanized ( ≥75μm) |

| Forged Steel, 8 connections per node |

| Supports up to 100m+ with proper engineering |

| EN 12810 / EN 12811 / ANSI / AS/NZS 1576 |

| 15+ Years (Under normal usage ) |

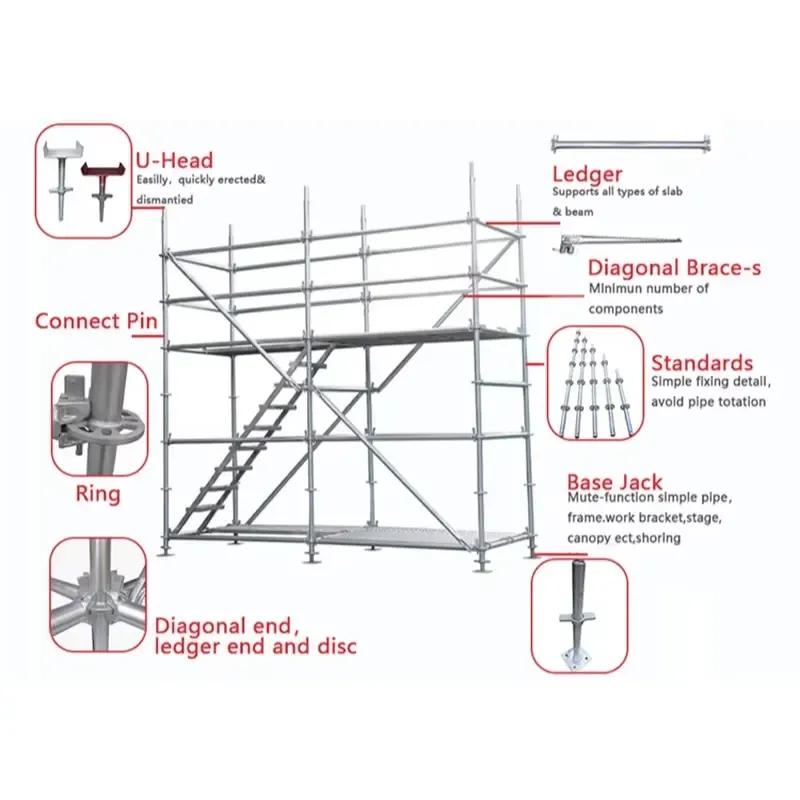

Product Features

- Unmatched Durability (HDG Technology): Our in-house Hot-Dipped Galvanization process ensures both inner and outer surfaces are coated. This effectively prevents rust from the inside out, extending the product life to over 15 years—ideal for rental fleets.

- High Load Bearing Capacity: The Q345B vertical standards combined with our mechanically welded rosettes allow for exceptional load transmission, making it suitable for heavy infrastructure shoring.

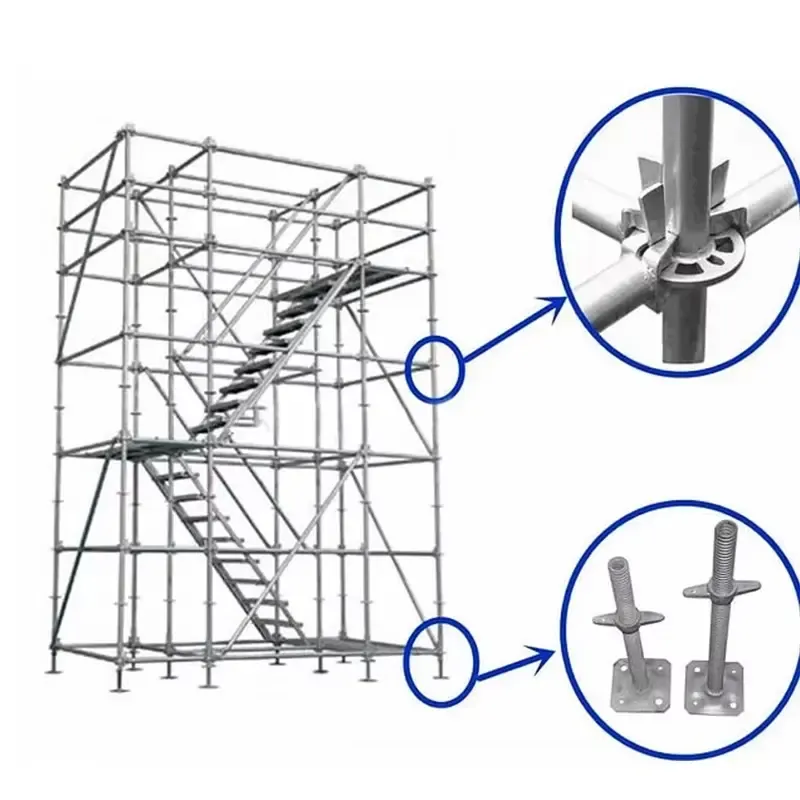

- 8-Way Connection Flexibility: The rosette allows up to 8 connections at various angles, enabling the scaffolding to curve and adapt to irregular building shapes (circular tanks, curved bridges).

- Safety & Stability: The wedge lock system tightens as load increases. Hyson’s strict QC ensures zero loose components, preventing structural shaking during high-altitude operations.

- Precision Manufacturing: We use CNC cutting and robotic welding to ensure strict length tolerances. This means components from different batches assemble seamlessly, eliminating on-site frustration.

Application Scenarios

- Bridge & Viaduct Construction: Used as heavy-duty shoring towers (Falsework) to support massive concrete formwork loads (e.g., casting box girders).

- Industrial Plant Maintenance: Flexible geometry fits around complex piping and machinery in refineries, power plants (like our Sudan Thermal Power Plant project), and chemical factories.

- Commercial High-Rises: Provides safe, stable working platforms for facade installation and masonry work.

- Event Structures: Rapid assembly for concert stages, grandstands, and temporary viewing decks.