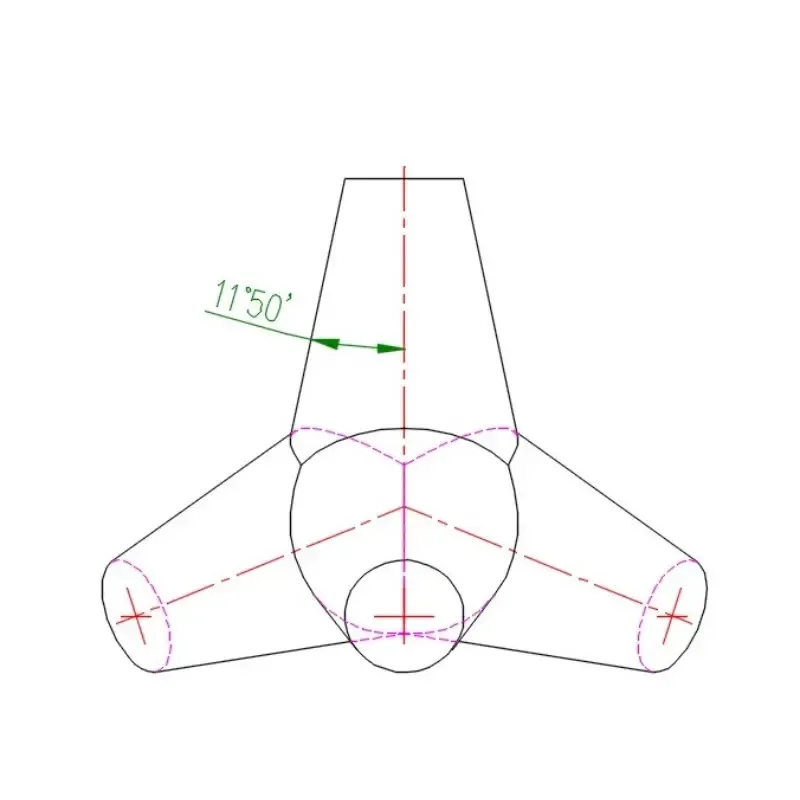

Hyson Industry’s Tetrapod Steel Moulds are the backbone of modern "breathable breakwaters." Designed to cast four-legged, interlocking concrete structures, our moulds enable the production of coastal defense units that effectively dissipate wave energy rather than blocking it.

Unlike traditional block moulds, Hyson’s solution focuses on hydrodynamic stability. Engineered with a low center of gravity (1/3 of edge height) and high-precision interlocking geometry, the resulting concrete units naturally interlace to resist sliding and tipping—even under typhoon conditions. Manufactured from premium structural steel with reinforced critical joints, our moulds withstand the intense vibration of precast yards, delivering a service life of 500+ cycles. Whether for reducing coastal erosion or creating artificial reefs, Hyson delivers the accuracy and durability global contractors demand.

Technical Specifications

| |

| High-quality Carbon Steel Q235 / Q345 |

| 4mm - 6mm (Customizable based on load calculation ) |

| 6mm - 8mm Standard Flat Bar or U-steel |

| High-strength Bolt & Nut Assembly |

| 1.5T - 25T (Depending on Tetrapod size ) |

| |

| 300+ Casting Cycles with proper maintenance |

| |

Product Features

- High-Efficiency Demoulding: Our modular design with polished inner walls (roughness Ra≤3.2μm) allows for rapid stripping. Experienced teams can complete demoulding in minutes, significantly boosting daily output.

- Structural Stability & Safety: The mould design ensures the concrete unit’s center of gravity is optimized. When deployed, the three legs naturally find stability, offering 30% higher anti-tipping torque compared to cubic blocks.

- Leak-Proof Precision: Utilizing laser cutting (±0.1mm accuracy) and robotic welding, our moulds have seamless joints that prevent slurry leakage, ensuring a "clean concrete" finish with no need for secondary grinding.

- Ecological Compatibility: Designed to create breakwaters with ~45% porosity. This allows water exchange and supports marine ecosystem recovery, meeting modern "Green Infrastructure" standards.

- Durable Investment: Built with thickened stiffeners and wear-resistant steel, minimizing maintenance costs and maximizing rental ROI.

Application Scenarios

- Coastal Breakwaters: Interlocking units form a permeable barrier that reduces wave run-up and protects harbors.

- Riverbank & Estuary Regulation: Stabilizes riverbeds and prevents erosion caused by strong currents in delta regions.

- Ecological Restoration (Artificial Reefs): The void spaces between tetrapods provide habitats for marine life (algae, fish, oysters), promoting biodiversity.

- Land Reclamation Defense: Acts as the primary armor layer for seawalls protecting newly reclaimed land.